Liberty Safety’s core purpose is to equip distributors with the necessary tools to enhance their safety culture. Liberty Safety constantly strives to achieve this goal by becoming an industrial partner with esteemed companies such as DuPont Personal Protection, renowned for their unwavering commitment to personal safety.

This comprehensive online hub contains an array of documents, articles, and multimedia resources. Users can find valuable insights into industry hazards, safety protocols, and guidance on appropriate Personal Protective Equipment (PPE) selection.

Whether you’re a seasoned risk management professional or a safety beginner, the DuPont Personal Protection Resource Center is an indispensable asset for everyone. Dive into the following sections for more insights.

Locating the DuPont Personal Protection Resource Center

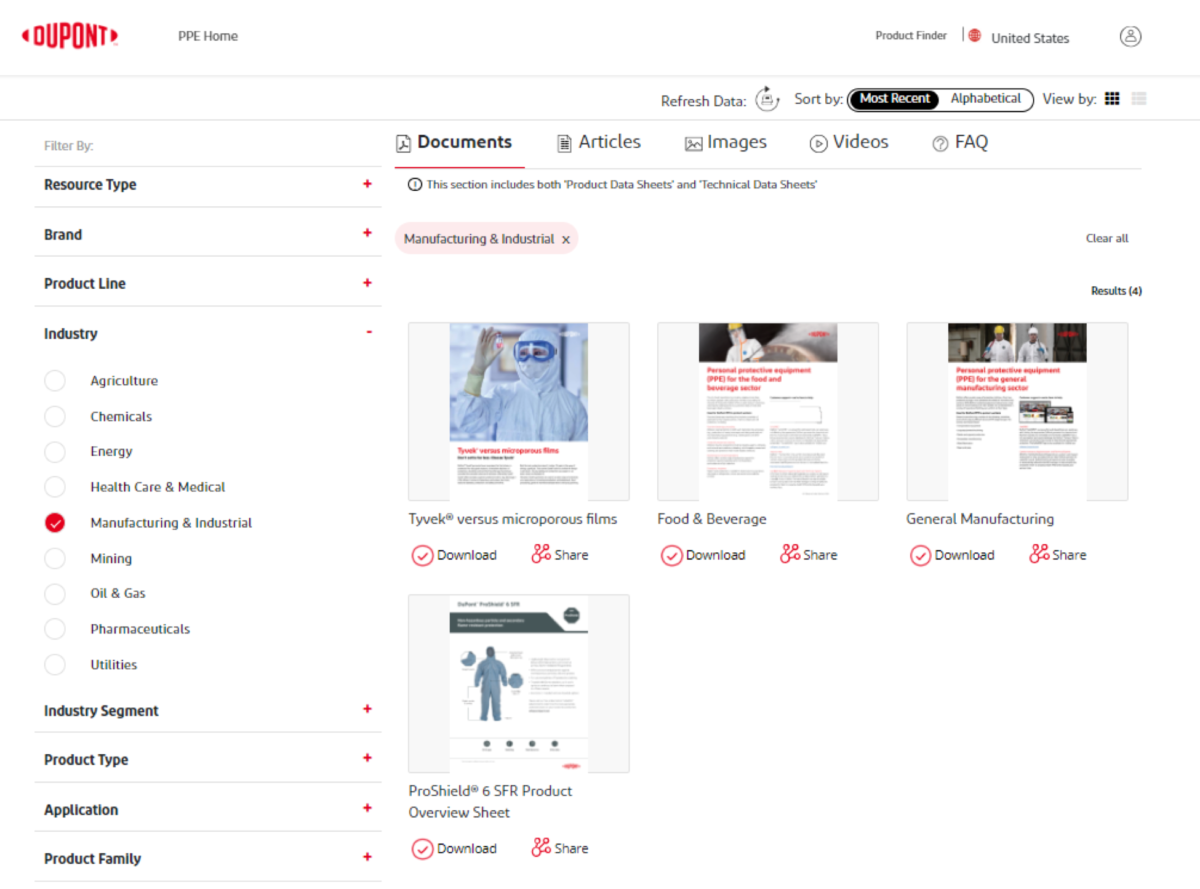

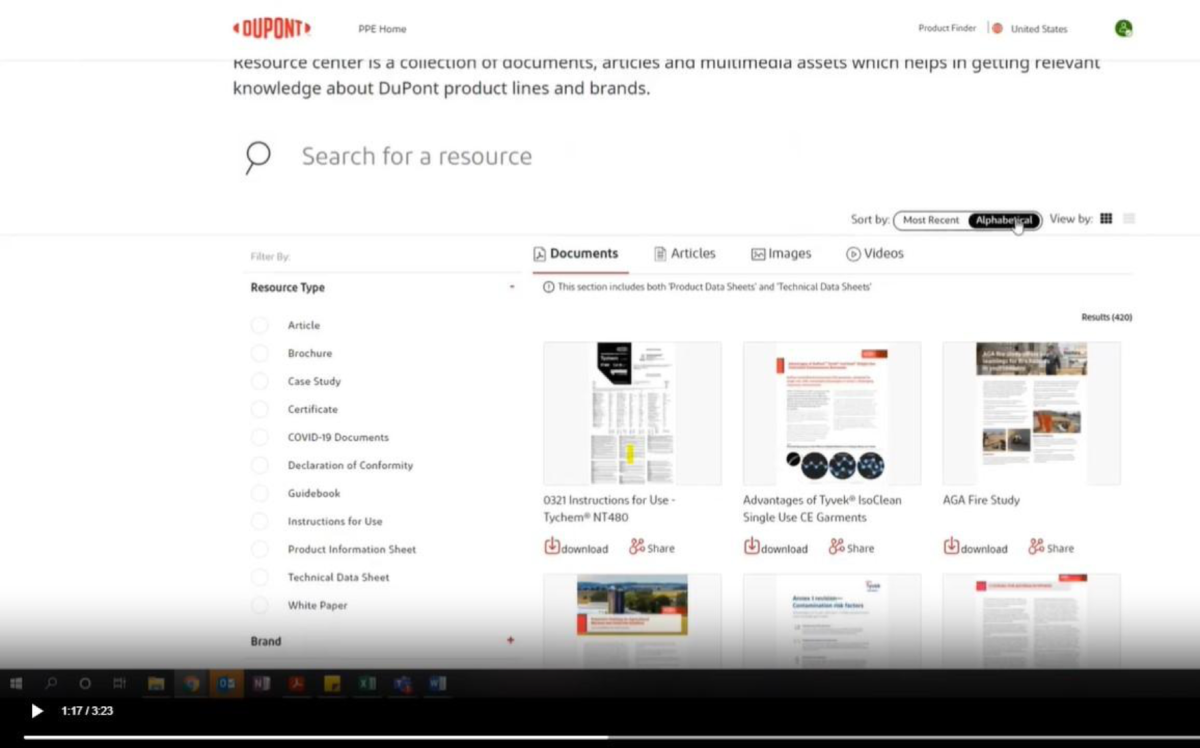

Begin your journey by navigating to the DuPont Personal Protection Resource Center website. Here, a plethora of resources await, available with the following library filters:

- Resource Type

- Industry

- Application

- Product Category

- Product Type

- Brand

- Product

- Language

Simply select a category and the search results will be refined and streamlined according to your preferences. Rest assured; the Resource Center receives frequent updates to provide you with the most up-to-date information.

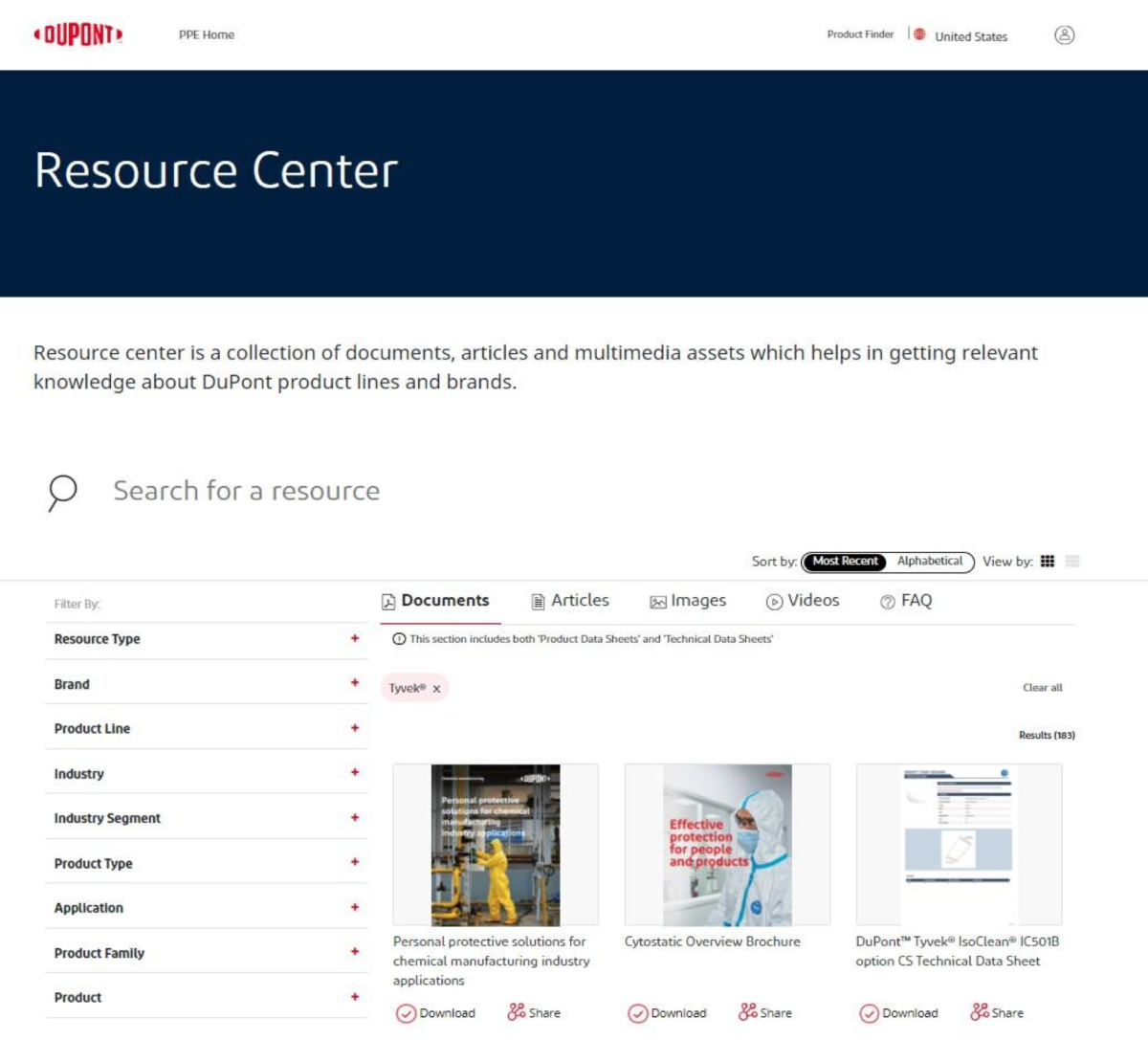

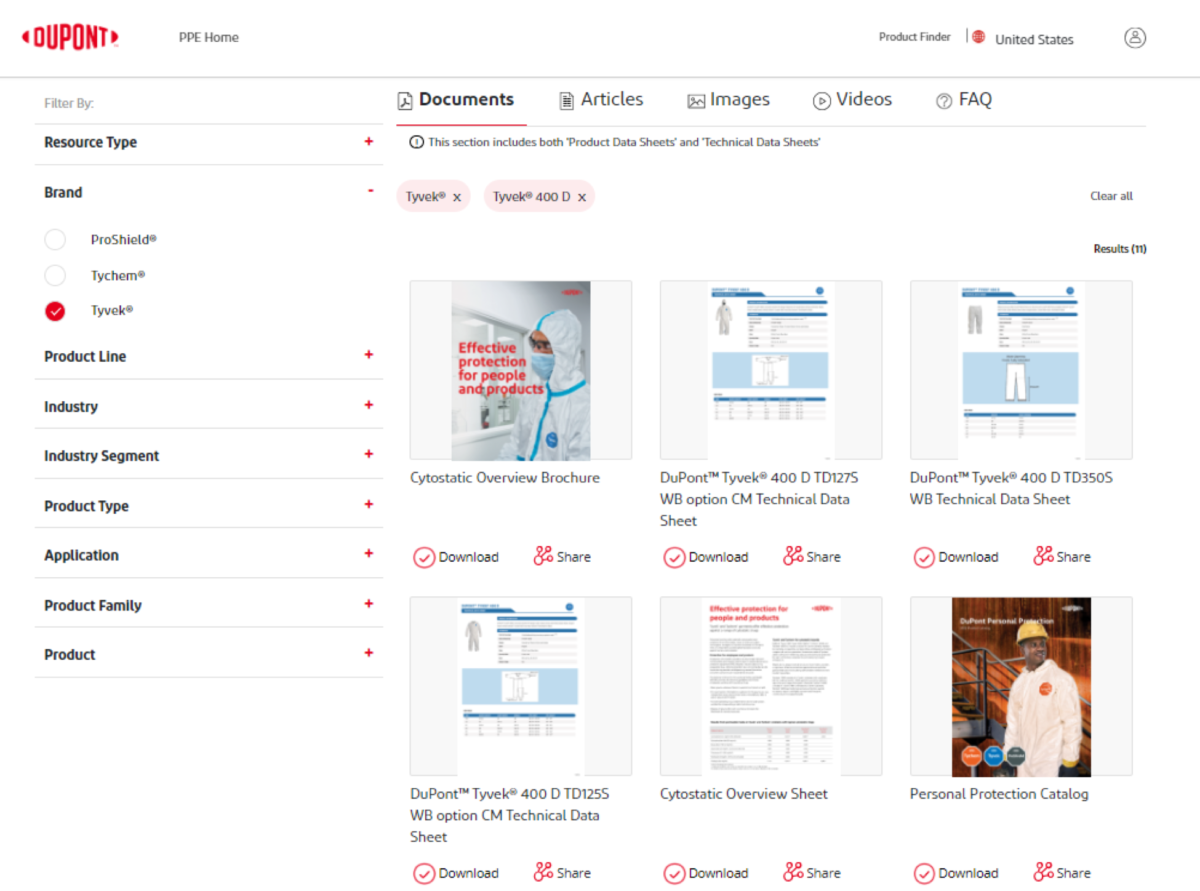

Navigating the Resource Center Homepage

The DuPont Personal Protection Resource Center makes it easy to find useful documents such as ‘Product Data Sheets’ and ‘Technical Data Sheets’, articles, case studies, images of products offered, videos, webinars, and as well as frequently asked questions (FAQs).

The Resource Center displays different sections where you’ll find a wealth of information on DuPont Personal Protection product lines and brands — designed to help you make informed decisions about which product suits your needs. Here’s the breakdown of every section:

- You’ll find product and technical data sheets within the documents section, perfect for anyone looking for detailed information about a particular product.

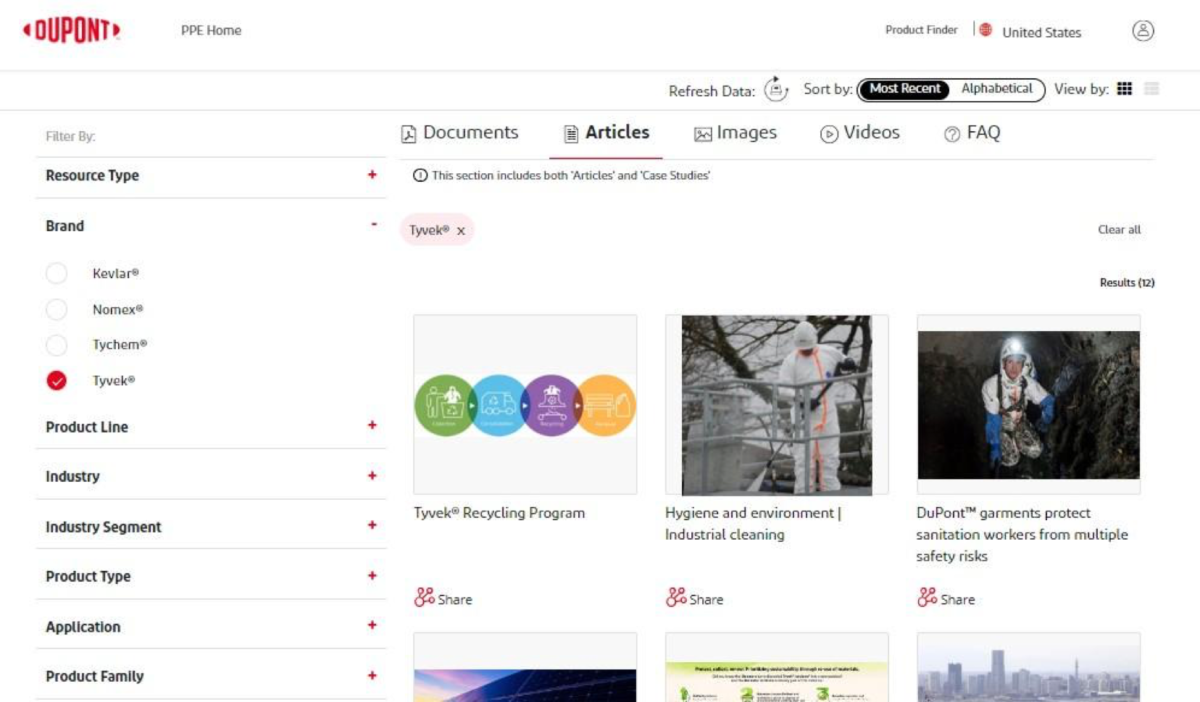

- The articles section includes case studies and articles, providing insights and ideas for anyone wanting to learn more about a specific application for DuPont Personal Protection products.

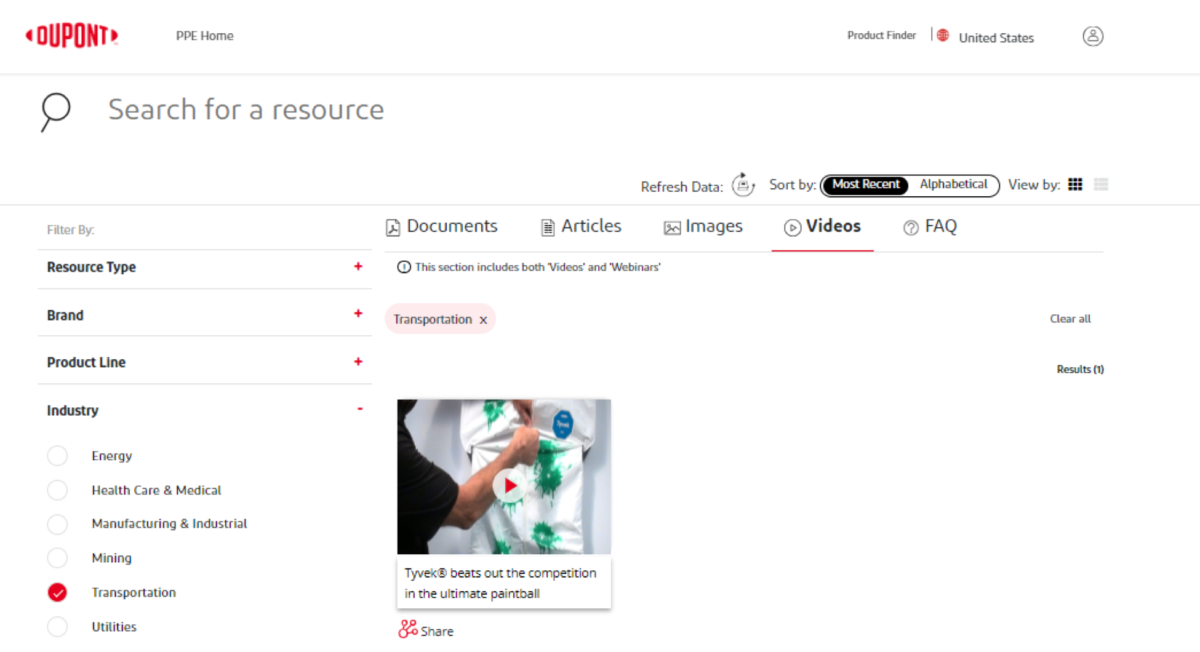

- The video section contains webinars and instructional product videos, making learning more about these products from anywhere easy.

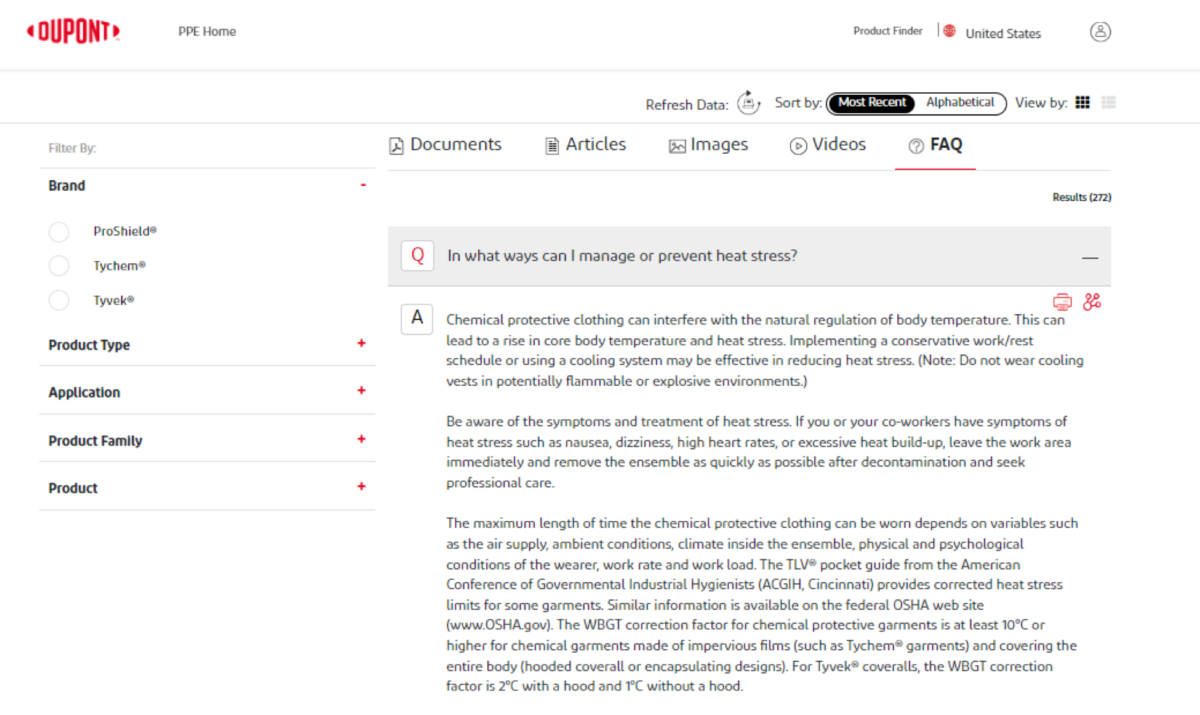

- If you still have questions, you’ll be delighted to find the FAQs tab, which offers concise, informative answers to frequently asked questions.

DuPont Personal Protection makes it easy for customers to access the important information they need to make informed decisions when researching, purchasing, and using their products. Customers can quickly get up-to-date information about the products and services available by providing these resources in one convenient location on its website.

Perks of Signing into DuPont.com for Access to Premium Content

Registering for a DuPont.com account opens doors to exclusive content and benefits:

- Exclusive Industry Content: With a DuPont.com account, you gain access to recent research and industry insights by DuPont Personal Protection experts.

- News and Trends: Stay in the loop with regular updates on blog posts, press releases, and announcements about new products or services.

- Intuitive Search Feature: Quickly locate required information without data overload.

- Tailored Product Information: Customizable preferences allow notifications based on your interests when new solutions are launched.

Honing Your Filter Skills in the Resource Center

Navigating through a treasure trove of information in the DuPont Personal Protection Resource Center could be overwhelming at first, but with the right approach to using filter options, it’s a breeze.

You can sort by topic, brand, industry, application, product family, and more. Combining different categories and filters yields narrowed-down results for your needs. For instance, if you’re looking for safety information regarding a particular type of worksite, you may want to use the “Industry” filter, with options like “Manufacturing & Industrial,” “Oil & Gas,” “Chemicals,” “Health Care & Medical” and more.

If you’re looking for information on a specific product, the “Brand,” “Product Family,” and “Product” filters can help narrow down the results.

For best results, we recommend using multiple filters under different categories to find resources specific to your search.

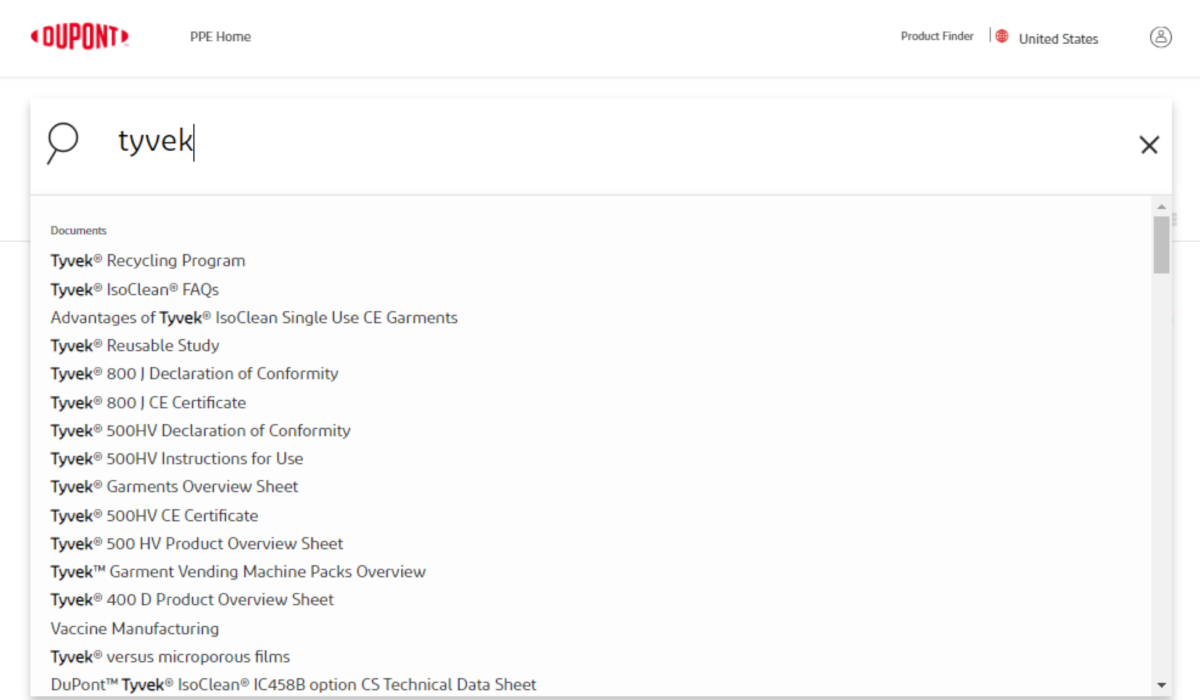

Harnessing the Power of the Search Function

The search function in the DuPont Personal Protection Resource Center offers an intuitive means of finding valuable information. Just enter your search terms and watch as possible matches populate in the drop-down menu. Search results are categorized under Documents, Articles, Images, Videos, and FAQs, simplifying your search process.

For instance, if you type “Tyvek” in the search bar, possible answers to your inquiry will appear, such as:

- Tyvek® 400 D Product Overview Sheet

- Tyvek® 500 HV Product Overview Sheet

- Tyvek® versus microporous films

- Tyvek® Recycling Program

- Tyvek® Reusable Study

By using specific, relevant keywords, you’ll find the most accurate results and smoothly navigate.

Accessing, Sharing, and Viewing Materials

The DuPont Personal Protection Resource Center offers materials for viewing, sharing, and downloading:

- Share videos and articles by clicking the share button and copying the link. Social media sharing is also available.

- To download documents and images, click the download button below each resource.

- You may also preview the document on the Resource Center before downloading and/or sharing.

Using a combination of these methods, you can use the resources in creative ways. Store files on your computer, print copies for offline review, or email useful materials to colleagues.

The DuPont Personal Protection Resource Center: An Empowering Knowledge Hub

Leverage the DuPont Personal Protection Resource Center to equip yourself with the knowledge needed to choose the best products for your specific requirements. With a special focus on industries exposed to hazardous conditions or materials, our industrial partner’s Resource Center is a crucial tool for promoting personal safety.

To learn more about the DuPont Personal Protection Resource Center, watch a quick video walkthrough here:

The Resource Center, with its vast array of resources, along with Liberty Safety’s commitment to superior service, empowers users with essential safety information.

Liberty Safety is proud to offer protective solutions from DuPont™, including DuPont™ Tyvek®, Tychem®, ProShield® and more. Shop for DuPont Personal Protection products here.