As temperatures rise during the summer months, outdoor workers face escalating challenges and safety risks. According to the U.S. Department of Labor’s Bureau of Labor Statistics (BLS), heat-related incidents resulted in an average of 38 fatalities annually and approximately 2,700 cases with days away from work from 2011 to 2019 (osha.gov).

These statistics underscore the critical importance of equipping yourself with the essential knowledge about heat stress to safeguard the well-being of workers on the job. In this comprehensive guide, we’ll explore practical strategies, proactive measures, and effective solutions to help you mitigate the risks of heat-related illnesses and ensure workplace safety in high-temperature work environments.

Understanding Heat Stress

Heat stress occurs when the body’s natural cooling mechanisms are overwhelmed by excessive heat exposure. While the body typically maintains an internal temperature of around 98.6°F (37°C), factors such as hot environments or physical exertion can disrupt this balance. In these conditions, the body may struggle to dissipate heat efficiently, leading to a rise in internal temperature.

Symptoms of heat stress become apparent when the body’s internal temperature exceeds approximately 100.4°F (38°C). At this point, individuals may experience a range of symptoms, including excessive sweating, dehydration, fatigue, dizziness, and nausea. If left untreated, heat stress can progress to more severe conditions such as heat exhaustion or heat stroke, which can pose significant health risks and even be life-threatening. Therefore, it is crucial for individuals to remain vigilant and proactive in managing their health and safety in high-temperature work environments, as the consequences of neglecting these symptoms can be severe.

Identifying Who’s at Risk

Construction workers are often deemed most susceptible to heat stress, given the unpredictable outdoor temperatures they encounter on job sites. However, heat stress permeates across various industries, impacting workers regardless of whether they work indoors or outdoors.

Numerous sectors face the dangers of heat stress, including:

- Outdoor industries: Construction, landscaping, agriculture, logging, postal & delivery, fisheries crews, and wildland firefighting.

- Indoor industries: Warehousing, food processing, foundries, manufacturing, automotive, and more.

These are just a few examples of industries where workers may be at risk of heat stress. It’s important to remember that heat stress can affect workers in any industry, regardless of whether they work indoors or outdoors. Recognizing this broad impact is essential for implementing effective heat stress prevention and response measures across all workspaces.

Tips for Heat Stress Prevention

- Hydration: Encourage frequent water breaks to prevent dehydration, even if workers don’t feel thirsty. Electrolyte-rich beverages can help replenish lost fluids and minerals.

- Schedule Management: Plan tasks during cooler times of the day and implement shaded rest areas to minimize heat exposure.

- Acclimatization: Gradually expose workers to hot environments, allowing their bodies to adapt to the conditions over time.

- PPE Selection: Opt for lightweight, moisture-wicking PPE that facilitates airflow and heat dissipation without compromising safety.

- Training and Education: Provide comprehensive training on heat stress awareness, early symptom recognition, and emergency response protocols to empower workers to protect themselves and their colleagues.

Recognizing Early Signs of Heat Stress

Identifying the early signs of heat-related illnesses is crucial for prompt intervention and preventing more severe conditions. From mild symptoms like heat rash and cramps to more serious issues such as heat exhaustion and heat stroke, it’s essential to remain vigilant.

Warning signs like excessive sweating, dizziness, nausea, and weakness should never be overlooked. Instead, they serve as vital cues for immediate action, including rest breaks, staying hydrated, and seeking medical attention if necessary.

Emergency Response

Swift action is imperative in cases of severe heat-related illness. Emergency response protocols prioritize moving affected individuals to a cool, shaded area as quickly as possible. Once there, loosening restrictive clothing and providing fluids, if appropriate, are essential steps to help lower body temperature and prevent further heat-related complications.

Additionally, it’s crucial to seek prompt medical attention, especially if symptoms of heat stroke, such as altered mental status, rapid pulse, and hot, dry skin, are observed. By following these protocols diligently, we can ensure the safety and well-being of workers in high-temperature work environments.

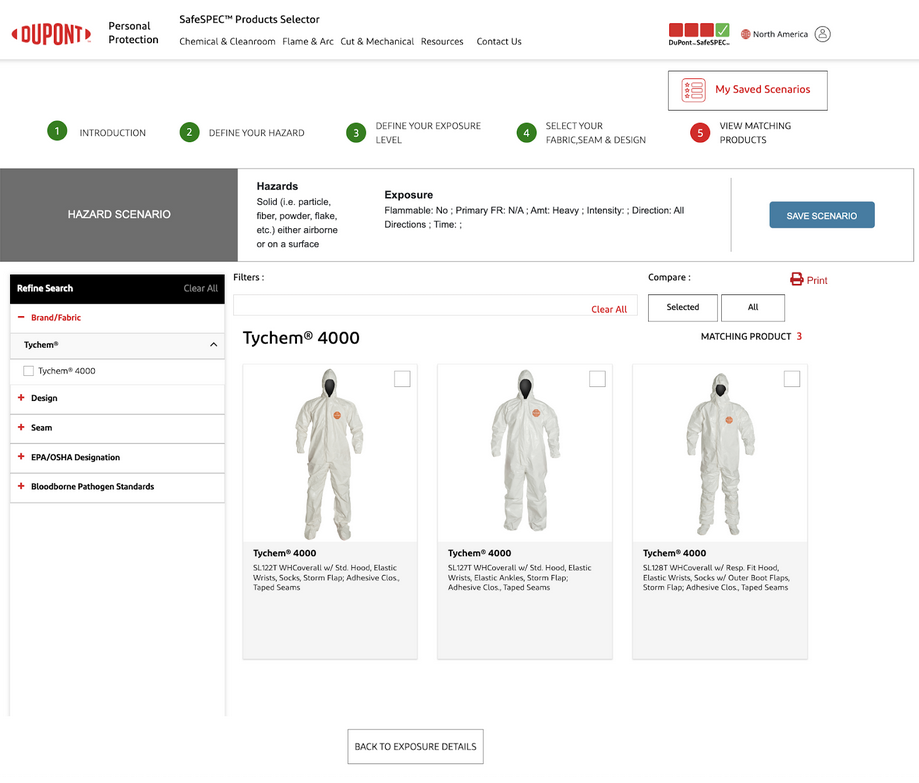

Choosing the Right PPE

Selecting the appropriate personal protective equipment (PPE) is crucial for ensuring safety and comfort in hot work environments. Our comprehensive range of Head-to-Toe PPE solutions are designed to meet the unique needs of professionals across diverse industries.

Explore our Summer Catalog for a full range of PPE designed to keep you cool and safe all season long!

🔗 Liberty Safety Summer Catalog

Conclusion

At Liberty Safety, we are committed to safeguarding the health and well-being of workers in hot work environments. Through innovative PPE solutions and expert guidance, we are dedicated to providing the tools and resources necessary to combat heat stress effectively.

By prioritizing prevention, recognizing early warning signs, and implementing proactive measures, we can mitigate risks and create a safer, more productive work environment for all. Together, let’s master heat stress prevention and ensure the protection and well-being of our workforce.

Your safety is our priority. It’s all part of our Freedom in Full Gear promise!